Anker stones

Last update April 8, 2022

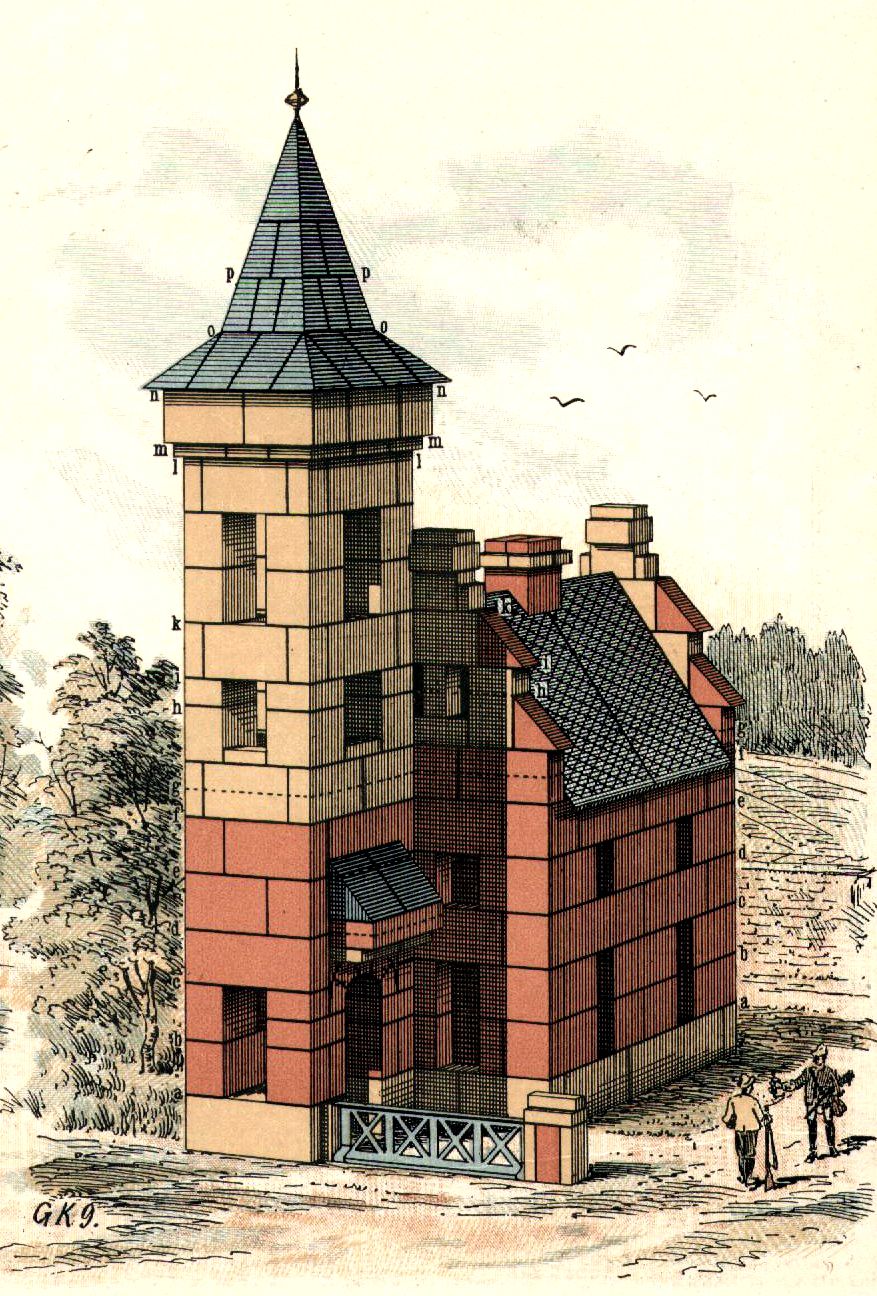

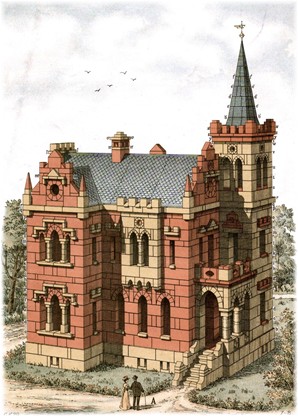

Hunting castle, DS 9 page 9

|

HistoryAround 1830 the pedagogue Friedrich Fröbel developed for his "Deutschen Kindergarten" boxes with wooden shapes: sphere, cone, cylinder and cube, to teach children in the age from 3 to 6 year, while playing, fundamental insight in the three-dimensional world. Exploring more suited construction materials for erecting miniature buildings than Fröbel's low weight and slippery wood, Gustav Lilienthal, the aviator Otto's brother, developed a new stone-like material from silver sand, chalk and raw lineseed oil. The components were mixed, pressed in the required shape, and subsequently baked at temperatures between 100 and 150 °C causing the lineseed oil to cure by oxidation. Using colours from local quarries, stones with the natural appearance of sandstone were obtained. Stones made by this principle had the appearance of real sandstone: they were heavy, rough and felt cool in the hand. The characteristic smell of the cured lineseed oil always surrounds them. Click here for a picture of a typical Anker stone of 25 x 25 x 12.5 mm. Because of their mechanical properties, the stones of an Anker building do not have to be glued or fixed in another way to get a stable building. They just rest upon each other like the building blocks in antique buildings. Gravity and a high friction coefficient give Anker buildings a surprisingly high resistance against shocks or small impacts. This even applies for extruding elements like balconies or bartizans. Of course the weight of the individual stones builds up to the weight of the complete Anker building. As an example, a building for NF34 using about 3000 stones weighs around 50 kg. Since Lilienthal bankrupted, not being able to commercialise his finding, the method and production equipment was sold to Adolph Richter who had established an industrial empire on medicines in Rudolstadt (Thüringen, Germany). Richter patented the stone making method in 1880. He and his employees developed the concept of Anker stones to a high level of sophistication. Being originally intended for children using small sets of 19 to 105 stones, new sets with more stone shapes were designed as an addiction to the existing sets. Someone who started with a Neue Folge (NF) stone set 6 of 105 stones could expand his collection in 14 steps to NF34 (3851 stones) by purchasing the subsequent supplement sets. |

|

While Fröbel's cylinder shape still kept playing its role, most stone shapes were based on a cube of 25 mm unity. Applying different values (integers or fractions) of the cube unity like 0.5, 0.25, 0.125, 1.25, 2.5, 4, a large number of new stone shapes were designed. In addition various sizes of roman arcs and gothic arcs were introduced, leading to over 1000 different stone shapes in total. Needless to say that the bigger stone sets were no longer suited for children but rather for grownups. In addition also a number of other, mostly smaller, stone sets were designed, the most important one being the VE/DS (Vernickeld Eisen/ Dach Steine) series. These series, having bit less stones than the NF, were enhanced by nickle-plated (VE) or lacquered (DS) metal parts. The largest set (VE/DS29) has 2348 stones, 283 stone roof tiles, and 362 metal parts for making roofs and bridges. After Richter's death in 1910 the prosperity of the Anker factory came to an end, business gradually decayed until the final termination in 1963 (after world war II, Rudolstadt was located in the former DDR). Fortunately, since 1995 Anker stones are produced again in Rudolstadt. Presently all NF sets until 34 are for sale as well as the "Grosse Burg supplement". To make use of the elaborate stone sets, also "software" in the form of building examples had to be devised. Richter added generally around 10 building examples for each set. The larger sets (from NF8 cq VE/DS 7 on) had a booklet with geometric drawings and another booklet containing the cross sections. More details about the history and other aspects of Anker stones may be found in Richters Anker-Steinbaukasten (English) or German by George Hardy. Anker stone collectors, builders and designers meet each other in the international "Club van Ankervrienden" (CVA) having at present around 250 members, meeting twice a year in Hilversum (NL). |

Gothic villa, VE 29 page 2 and 3

|

|

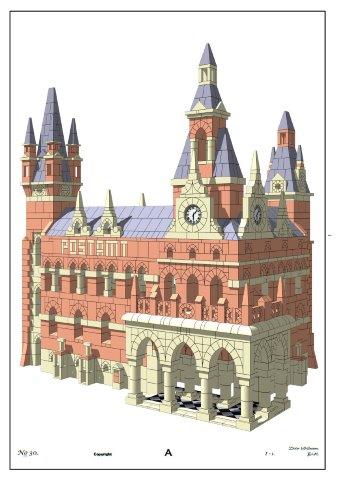

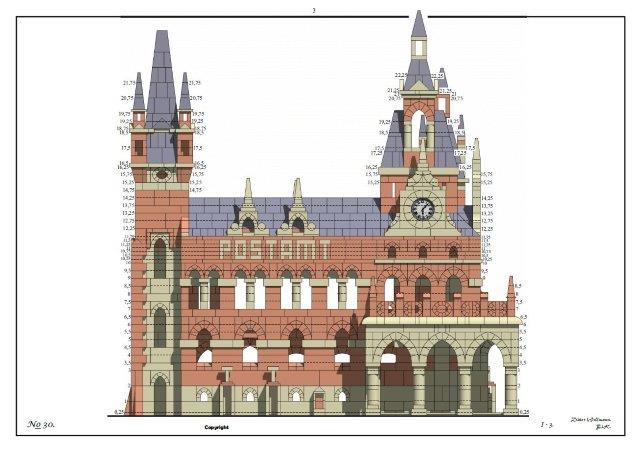

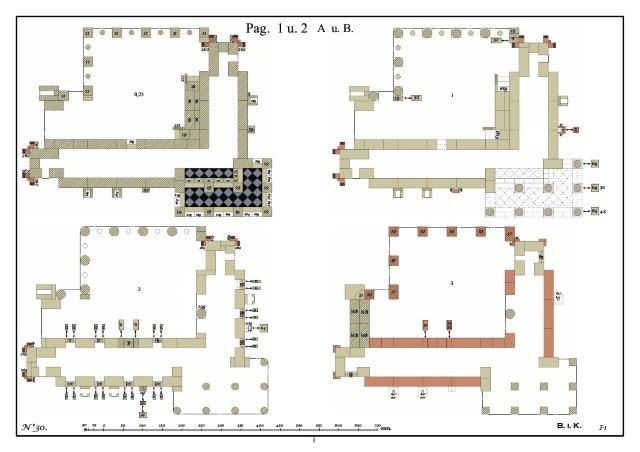

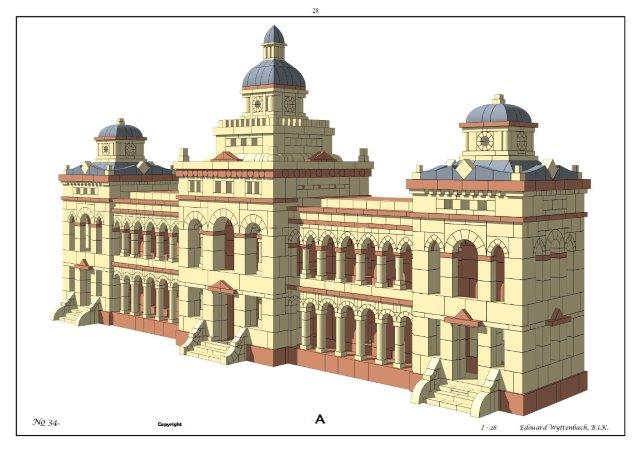

Postamt for NF30 by Dieter Wellmann

Postamt gable with layer indication

Postamt layers 0,25 - 3

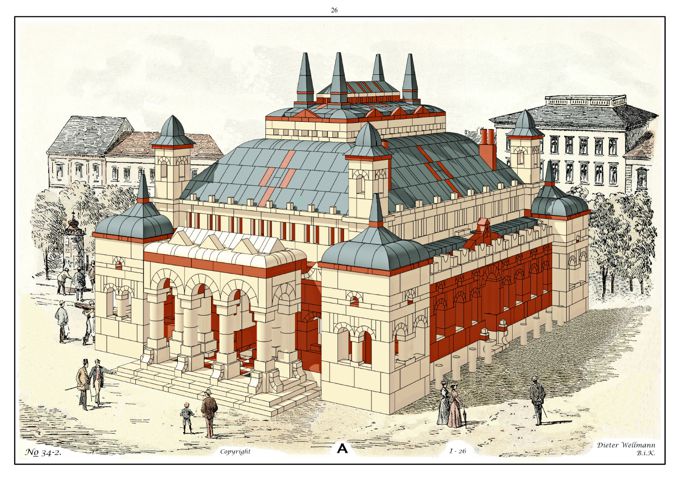

Event hall Mainz for NF34 by Dieter Wellmann

Shipping company in Port Said for NF34 Edouard Wyttenbach . |

Baukunst im KleinenBaukunst im Kleinen (BiK) is a CVA committee reviewing new designs from Ankerfriends. Purpose of BiK is to check if the design may be built by everyone who has the stone set it is intended for. After the review, publication drawings are made and the design is published on the internet as part of a design booklet. BiK has set the following criteria for a new design:

The formal regulation of BiK is found in Dutch or English. Presently BiK follows six steps from an incoming design to the completed publication in the design booklet:

Publishing

The designs are published in the form of Richter style booklets. They are printed in A3 format in limited quantities (40 - 60 pieces) and can also be downloaded via the BiK page. The drawings (views and cross sections) are made by †AnkerPlan 1.5 and 2.2 and arranged in Richter style A3 pages using CorelDraw 2019. We still welcome new designs for NF 34. Please send them in the following way. Talks on BiK for downloading

Papers about BiK published in the CVA magazine (MLB), all in Dutch

Links to other Anker sites

Designs under review (may contain errors, only for BiK members)

Completed booklets Note that the booklets for NF24 and higher are intended for A3 printing format. †AnkerPlan is a 3D CAD program. Version 1.0 - 1.5 had been developed

by a commercial firm and is especially adapted for designing Anker buildings. Ankerplan 2 has been completely revised and expanded by Michael Erhard and Andreas Rhodin. Available for CVA members only. |